こんにちは、ディレクターの西城です。

私が普段従事している案件は、設計からデザイン、コーディングまでを一連の流れとする制作ディレクションが大半です。これまで様々な案件をとおして、ディレクターとしての経験値もそれなりに積んできましたが、時には経験したことのない種類の案件に出会うこともあります。

最近の例では、「別会社が実装したサイトのソース部分を、クライアントから用意されたデザインガイドラインやパーツ集に合わせて組み替えていく」というプロジェクトがありました。通常の制作ディレクションとは異なる特殊な案件で苦労しましたが、そこから得た反省点や新たな学びについて、今回はご紹介したいと思います。

「指示書を作らない」という選択

通常、ウェブサイトを制作する際には、必ず「指示書」と呼ばれるドキュメントを用意します。クライアントと取り決めた内容や設計段階で考えたことを指示書に落としていくことで、関わるメンバー間の認識に齟齬が生じないようにするためです。また、指示書があることで、コーダーは迷うこと無く、効率的に制作を進めることができます。

今回のプロジェクトでも、案件着手前のキックオフミーティングでは、弊社側で指示書を作成することを申し入れていました。しかし、「作業内容的にソースの置き換え対応なので、わざわざ指示書を作らなくても大丈夫では?」という先方の意向もあり、指示書を用意せずに案件がスタートすることになりました。

以下のような流れで作業を進めます。

- コーダーが、対象ページとデザインガイドライン及びパーツ集を見比べて、必要となるパーツを洗い出す。

- そのパーツを元に、ソースを置き換えていく。

当初は、デザインガイドラインやパーツ集があるということで、洗い出せば、特定のパーツにたどり着き、多少工数はかかっても問題なく進められるだろうとの認識でいました。

コーダーに掛かる思わぬ負荷

しかし、中盤に入って、コーダー側の作業が事前に見積もった工数よりも実際はかなり溢れていることが分かりました。その原因を探っていったところ、「必要となるパーツの洗い出し」の作業がネックになっていることが分かったのです。

かなり工数が押し始めていたため、コーダーと相談して、試しに私の方で後半の画面の洗い出しを行うことに。自分で洗い出してみると、以下のような問題点が浮かび上がってきました。

- 特定のパーツを洗い出すだけでも時間がかかる

- それ以上に、ガイドラインやパーツ集に必ずしも当てはまらない箇所が多い

- 推測で仮説を導き出すまでに結構な工数がかかる

そこで、これまでコーダーにまかせていたパーツの精査を、ディレクターである私が行うことに変更。当てはまりそうなパーツも、それで本当に問題ないかをクライアントと確認をして、確認が済んだものをコーダーに実装してもらうことによって、後半は巻き返して無事ゴールへとたどり着くことができました。

後日、クライアントからは「このようなモジュールを作るやり方に慣れておらず、どういう情報があれば問題なく行えるのか予測できていなかった」というお話を伺いました。

今回の場合も、通常の「指示書を用意する」というセオリーに沿って、最初に1ページ洗い出しをして工数をシミュレーションし、そのうえで、ソースを置き換えていくのにどういう情報が揃っている必要があるのかを先方に明確に伝えていれば、このようなミスコミュニケーションは生まれなかったと思います。

やはり、案件の旗振り役である自分が、もう少し慎重に案件のタイプを見極めるべきだったと反省するとともに、判断することの重要性を改めて感じました。

クライアントとの密なコミュニケーション

また、今回の案件をリカバリするにで非常に役立ったのが Google のツールです。

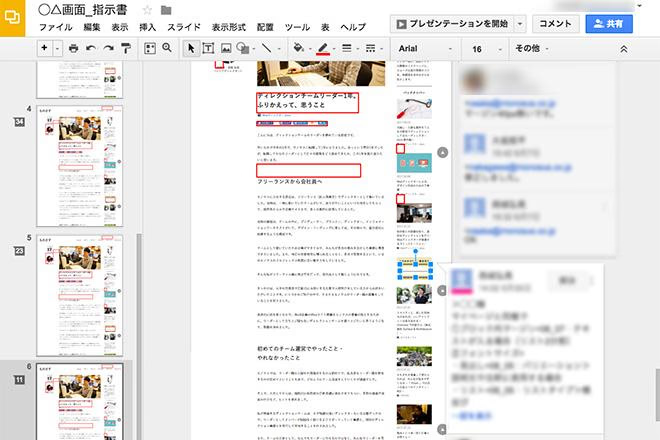

後半から指示書を復活させてパーツ精査を行いましたが、今回はパーツの特定が難しいページが多く、1ページだけでもかなりの数の仮説のコメントが生まれました。そこで、Googleスライドを活用して、クライアントと相互にオンライン上で知見の集約を行うことで、フィードバックや確認など密なコミュニケーションが可能になり、洗い出しの作業がスピードアップした結果、リカバリすることができたと思います。

Googleスライドを使った指示書のイメージ。クライアントとオンラインでコメントをやり取りできるので確認作業もスムーズです。

Googleスライドは社内のコーダーとも共有していたため、洗い出し後の実装時で不明なことがある場合でも、コーダーからオンライン上で、社内のテクニカル担当やクライアントに直接質問するなど、ケースに応じてコメントを通知することができ、スムーズに作業に取り組めたのではないかと思います。

クライアントからもページ全体を見直す良いきっかけになったという言葉もいただき、この事前準備を最初から行えていたら、ゴールまでの景色はもっと違っていたんだろうな…と改めて思った次第です。

※参考:パーツ集については、松永が書いた記事「工数削減!「パーツ集」を使って運用業務をスピードアップ」もご覧ください。

案件の「旗振り役」として

ディレクターは、ゴールに向けて状況を的確に判断して、旗を振っていく必要があるので、思い込みで進めていくと、スケジュールの遅延を招いたり、クライアントが望むものに辿り着けなくなってしまいます。そのためにも、制作に入る前の事前準備には時間をかけて、お互いに一緒の方向を見て進めるようにしなくてはなりません。

着手前にすりあわせる認識が、その後の工数にも大きく影響してくるので、特に今まで経験したことのないタイプの案件では、慎重にプロジェクトを進めていく必要があります。また、同じ方向を見てスタートした場合でも、クライアントや制作側に必要以上の負担がかかっていないか、都度状況を見極めて適切な旗振りを行うことで、クライアント、制作側、双方にとって満足度の高い仕事に繋げることができると思います。

クライアントからも制作側からも「また一緒に仕事をしたい!」と言ってもらえるような、そんな仕事を目指して、今後もディレクションを行っていきたいと思います。