こんにちはクリエイティブ部 部長の上井です。

今回で3回目となる「プロマネ塾」の連載。

前回はプロジェクト管理の基本であり、計画・着手時に全体像を構造的に把握するためのWBS構築についてお話しました。

連載第1回で紹介しましたが、プロジェクトとは、

独自のプロダクト、サービス、所産を創造するために実施する有期性のある業務

と定義されます。

決められたスケジュールで目的を達成する、非定型の業務を「プロジェクト」と呼びますが、商業的な成功に導くためにはコスト管理の視点を忘れることはできません。

第 3 回目のお題は、「WBS構築について その2 スケジュール・予算を立てる」 。

プロジェクト管理に必要な、見積りとスケジュール立案についてお話したいと思います。

連載目次

- 開発工程モデルについて(4月21日公開)

- WBS構築について その1 プロジェクトの筋道を立てる (6月15日公開)

- WBS構築について その2 スケジュール・予算を立てる( ←今回)

- QCD(Quality, Cost, Delivery) 〜10月公開予定〜

- 品質管理、品質保証について〜12月公開予定〜

- プロジェクトの前後を知ろう 〜2月公開予定〜

1. 見積りの作成

プロジェクトの全体像を把握するには、要求仕様、予算、スケジュールの3つの要素を明らかにする必要があります。

このうち「予算」「スケジュール」を立案するために必要な準備が、WBS(Work Breakdown Structure)だといえるでしょう。

以下のような手順でプロジェクトの要求仕様から予算、スケジュールを計画していきます。

① 要求仕様とWBSをもとに、要員の計画を立てる(難易度・数量の整理)

② 上記のリソース計画に基づき見積りを作成(予算立案)

③ 上記のリソース計画に基づきスケジュールを立てる(スケジュール立案)

④ 要求仕様への対応方針、見積り、スケジュールを調整する

それでは、まず見積りの作成手順を説明していきます。

(1)各工程の難易度を整理し、必要なスキルセットを整理する

WBSの各工程ごとに、作業の難易度に応じた要員に求められるスキルセットを整理します。

ここのスキルセットは、① 対応技術レベル、② 時間あたり単価、③ 単位時間あたりの生産量 で把握するようにします。また、プロジェクトの計画立案における要員の計画は、属人化せずに、対応可能な難易度でランク付けした標準モデルを設定します。

[難易度のランク付けの例(デザイン工程)]

- Sランク :案件固有の要求仕様に対応できるスキルレベル

- Aランク :グランドデザイン作成、デザインの品質管理ができる

- Bランク :グランドデザインに基づいた画面デザイン作成に対応できる

-

Cランク :ひながたに基づいた量産、画像素材の準備に対応できる

(2)各工程の成果物の数量を、設計方針を踏まえて整理する

連載第1回の「ウォーターフォールモデル」で説明したとおり、各工程のアウトプット(成果物)が、次の工程のインプット(前提条件)となりプロジェクトは構成されます。

各工程の作業量を算出するために、工程ごとの制作数量を確認します。

モノサスで手がけることが多い、数百ページ以上の中大規模サイトのリニューアルの場合、クライアントごとの独自性を持たせることと合わせて、設計・デザイン・制作の標準化によるコスト、スケジュールの低減が求められます。

作業量の算出を行うためには、全体数量を把握することと合わせて、標準化に対する設計方針を踏まえた、作業手順、作業範囲を明らかにする必要があります。

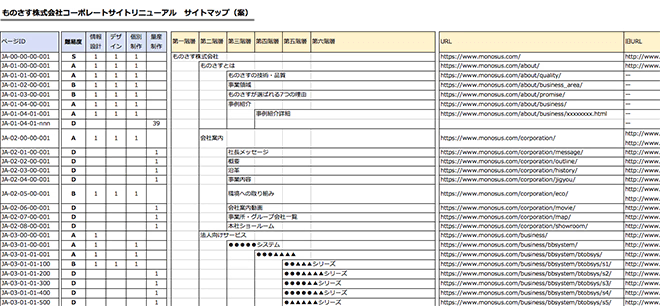

ページリストを作成し、「設計の検討手順」「デザインの検討手順、作成手順」「コーディングの作成手順」により工程を分解し、各工程の制作数量を整理します。

図:制作難易度のランクわけを記入したページリスト(例)

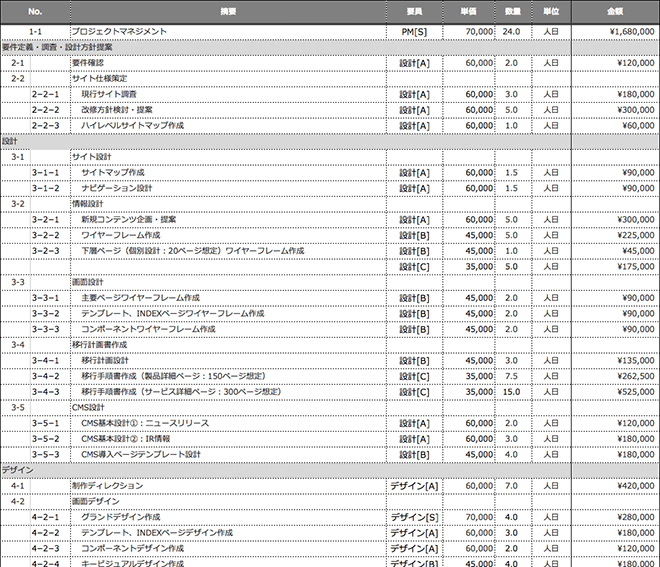

(3)要員のスキルセットと制作数量による積算を行う

(2)で整理した制作数量を、(1)で整理したスキルセットの要員が対応した場合の工数を算出します。

「要員の単価」×「工数」により工程ごとの費用を算出します。

また、コーディング制作の進行管理費などのマネジメントコストは、制作工程の費用の10〜20%に設定するなど、算出基準を設定します。

このように、積算による見積りを行うことが、コスト計画の検討ではとても重要です。

「各工程の要求仕様(難易度)=要員の単価」「制作数量」を数値化することで、仕様変更や制作数量の変更が生じた場合にも、変更内容を定量的に把握して対応することが可能となるからです。

図:見積書(例)

2. スケジュールの作成

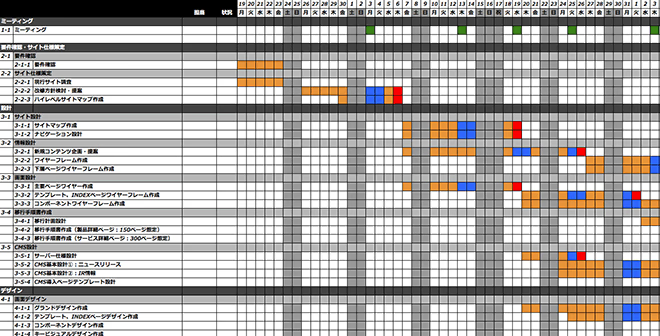

見積りで算出した作業工数に基づいて、スケジュール作成を行います。

以下の点に留意して、ウォーターフォールモデルの考え方で作成していきます。

- ウォーターフォールモデルにおける「前工程のアウトプット=後工程のインプッット」の時系列が保たれていることを確認する。

- クライアントによる「確認」「承認」のプロセスを設定する。

ウォーターフォールモデルは、プロジェクトの各工程を時系列に並べる最も基本的な開発工程モデルです。詳しくは連載第1回の記事を参照してください。

図:スケジュール(例)

3. スケジュール、見積りの調整

作業工数の積算による見積り、プロジェクトスタートからウォーターフォールモデルに沿って作成したスケジュールは、想定される予算や納品期日に納まらないことが往々にして起こります。

そこで、見積り、スケジュールを予算、納品期日の条件に納めるための調整を行うことになります。

(1)プロジェクト期間を短縮したい

要員の追加による調整を検討します。

標準化した下層ページの画面設計や画面デザイン、コーディングの制作の工程などにおいて、対応する要員を増やすことで対応期間を短縮する方法です。

[対応例:制作工数が、30人日のコーディング制作の場合]

① 1名のコーダーで実施する場合

- 制作仕様の確認:1営業日(1人日)

- コーディング制作:29営業日(29人日)

→30営業日(約1ヶ月半の工期が必要)、30人日(45千円 × 30 = 1,350千円)

② 3名のコーダーで実施する場合

複数のメンバーで制作を行う場合、コードの記述ルールの徹底や共有ファイルを変更する際のメンバー間への通知など情報共有のためのコミュニケーションが必要となります。

そのため、要員を3倍にすれば制作期間が3分の1に短縮できるということではありません。

- 制作仕様の確認:1営業日(1人日×3名=3人日)

- コーディング制作

1人日=8時間 → 29人日=232時間 の制作時間が必要

毎日の業務着手時、業務終了時に、15分ずつミーティング(合計0.5時間)を実施する場合

1人日=7.5時間 の制作時間となる(8時間-0.5時間)

→ 232時間 ÷ 7.5 = 31人日

→ 31人日を3名で実施するので、11営業日の制作期間が必要

→12営業日(約2.5週間の工期に短縮)

34人日(45千円 × 34 = 1,530千円、約13%のコスト上昇)

上記の例では、制作期間は、30営業日→12営業日 と 40%に短縮できるが、コストは約13% 上昇しています。

(2)予算を削減したい

設計方針の変更や数量の削減による調整を行います。

要求仕様の難易度を下げ、単価が低い要員による対応を可能とすることで、費用を削減することができるかを検討します。

また、制作範囲の縮小など、制作数量の削減による費用削減が可能かを検討します。

4. QCD を意識したプロジェクト要件の把握

見積り、スケジュールの立案では、「各工程の要求仕様(難易度)=要員の単価」「制作数量」を数値化することが必要です。

この数値化の際に意識する視点が「QCD」です。

これは、「Quality」「Cost」「Delivery」の頭文字を取った言葉で、プロジェクト要件を定量化して把握するための重要な3つの評価軸です。

一般的には、「Quality:品質」「Cost:費用」「Delivery:納期」と紹介されることが多いのですが、プロジェクトにおける段階によってその視点は異なります。

今回お話しした、見積り、スケジュール作成においては、以下の視点で各工程を数量化しました。

Quality :要求仕様(難易度)

Cost :スキルセットに応じた要員の単価/単位時間あたりの制作数量

Delivery :工期

「QCD」は、プロジェクト実施に必要となる人的資源を定量的に把握する際の重要な視点です。

詳しくは、「プロマネ塾」第4回でお話ししたいと思います。

第3回目は、プロジェクト実施に向けて、WBSに基づいたスケジュール立案や、見積り作成についてお話ししました。

次回は、プロジェクトを構成する様々な要素を定量的に把握するために必要な視点「QCD(Quality, Cost, Delivery)」について触れていきます。

それではまた、10月に。