In the second part of the "Let's Make Monosas Beer" project, we will introduce the actual process of making beer. From here on, the body double, Saito, who cannot drink alcohol, will be explaining the process. (In his normal job, he is in charge of quality control.)

[Part 1] Introduction: The reason for making beer, the background, and the passion for making beer

[Part 2] Brewing: The beer brewing process at the brewery - What it was like on the day

[Part 3] Finished and toasting: Before ~ Cheers! ~ After

We visited the "Handmade Beer Workshop" at Kiuchi Brewery in Naka City, Ibaraki Prefecture. Infection control measures were in place, so we were able to work with peace of mind.

This means you can make your own original beer to suit your taste, but will they be able to successfully create a ``Monosasu-like beer''?

From here, we will be taking you step by step through the beer-making process as shown to us by Kiuchi Sake Brewery.

1. Recipe discussion

First, we had a meeting while tasting the beers. We chose the base beer style, alcohol content, bitterness, and hops. It was a really fun process.

To select hops, try smelling them one by one or sniffing two at the same time.

Coming up with original flavors and aromas to match an image seems to be more fun than I imagined.

2. Weighing and crushing malt

According to the recipe, the malt that is the raw material for beer is measured out, collected, and crushed by machine. This is where the first heavy lifting begins.

3. Mixing

The crushed malt is then put into the kettle where the malting process will take place and mixed with warm water.

The wort is poured out from the tap under the kettle and returned from the top. This is done to circulate the wort so that it is well mixed.

The second heavy lifting came immediately. I did it about five times while trying to mix it evenly. It was up and down squats in the heat.

4. Heating and saccharification

When the temperature rises to 65 degrees, the enzymes become active and the starch in the malt turns into sugar. My notes said, "Close the lid and brew for 40 minutes while keeping the temperature constant." Take a break.

5. Iodine test

We will conduct a final test to see if the sugar has been converted to sugar using iodine solution. It's like the one we saw in elementary school science class, where we drip iodine solution and check the color change.

6. Mashout

The temperature of the wort is raised to 76°C to stop the activity of enzymes.

7. Filtration and tasting

The circulation process continues again. This is done quietly. Gradually, the wort becomes clearer, its color becomes brighter, and the unpleasant flavors are removed.

During this process, we chanted, "Be delicious, be delicious!"

I'm tasting it. It has a strong sweetness and is really delicious.

8. Transfer and Sparging

The wort that has been trickling out of the tap on the kettle is now moved to the kettle for boiling.

At the same time, the malt is poured over with boiling water using a watering can to extract all of the malt's extract. The water and the malt gradually separate. The reason for using a watering can is that the water pressure can be applied gently.

There is a lot to do and this is the most hectic process.

There was a lot of movement up and down and left and right, so I couldn't take my eyes off it, so I dropped my camera and notebook and joined in. It was a good time for the three of us to be there.

Since the two of them cannot leave their posts, I act like a manager and hand them beer to keep them hydrated.

9. Removal of malt grains

The malt residue is removed from the mash kettle.

10. Boiling and adding hops

The wort is sterilized and boiled to bring out a deeper flavor, and then the hops are added.

When they were measuring the hops, the two of them were like doctors, saying things like, "That's chemistry," and "Hmmmm." The containers they used were very cute, heart-shaped.

11. Whirlpool Whirlpool Rest

Once the boil is complete, stir and let the wort rest.

12. Wort cooling

The yeast is then cooled quickly and transferred to a fermentation vessel. During this process, the machine is operated with excitement.

And finally, we had the chance to taste the wort.

This is a tasting of the wort that is closest to beer, with the addition of hops.

From this point on, Kiuchi Sake Brewery will handle the fermentation, maturation, and bottling, so all that's left for us to do is wait and look forward!

The work took about five hours, including lunch. The long, long work was finally over.

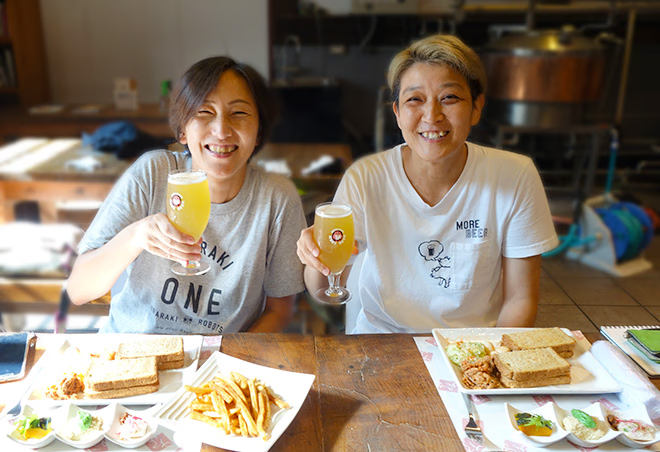

In between brewing beer, we also had lunch, enjoying Kiuchi Brewery's beer.

The sour and salty taste of the mackerel sandwich is a welcome relief for your hot and tired body.

Go to the convenience store and buy some beer, then after eating, change into a beer T-shirt and feel refreshed!

Thank you to Terakado from Kiuchi Sake Brewery for helping us out for such a long time that day, we had a very enjoyable time!

On the way home on the train, the two of them soon dozed off.

Maybe I was dreaming about everyone drinking the beer we made. Thank you for your hard work!

This series about beer brewing will end with everyone enjoying the finished beer!

■ Article from "Let's Make Monosasuki Beer"

[Part 1] Introduction: The reason for making beer, the background, and the passion for making beer

[Part 2] Brewing: The beer brewing process at the brewery - What it was like on the day

[Part 3] Finished and toasting: Before ~ Cheers! ~ After